RK CHAIN AND EXCEL RIM MAINTENANCE AND FAQ

Below are the frequently asked RK Chain and Excel Rim Maintenance questions that we receive. If your question is not shown, please feel free to use our live chat feature or simply email or call us direct. Maintenance is a crucial step to ensuring a long life of your chain; we are more than happy to help you with any questions you may have.

RK CHAIN FAQ

How Should I Maintain My Sealed Chain?

All motorcycle chain regardless of brand is a consumable product; which means that it will not last forever and will eventually need to be replaced. RK Chain suggests that chains need to be replaced every 20,000 miles and every 3,000 miles for non-sealed chains. You should also change both the front and rear sprocket whenever you replace the chain.

RK Chain recommends cleaning a sealed chain with only a mineral based O ring safe chain cleaner. Do not use kerosene, mineral spirits, diesel fuel, brake cleaner, motor oil or any caustic chemicals because that can damage the seals. RK recommends that you douse a rag with the mineral based O ring cleaner and wipe the dirt off the chain. Do not use a wire brush or hard bristle brush to clean a sealed chain. The wire or hard bristles can damage the seals reducing the life of the chain.

RK Chain recommends that after cleaning the chain and before lubrication, go for a short ride around the block to remove most of the chain cleaner and or water from the chain. RK recommends that you then follow up with a quality chain lubricant designed for sealed chains while the chain is still warm.

WE HIGHLY RECOMMEND USING A MOTORCYCLE O-RING CHAIN SPECIFIC CLEANER AND LUBE.

How Should I Maintain My Non-Sealed Chain?

All motorcycle chains regardless of brand is a consumable product; which means that it will not last forever and will eventually need to be replaced. RK Chain suggests that chains need to be replaced every 20,000 miles and every 3,000 miles for non-sealed chains. You should also change both the front and rear sprocket whenever you replace the chain.

Cleaning a non sealed chain is the same as a sealed chain. RK Chain recommends cleaning a non-sealed chain with only a mineral based O ring safe chain cleaner. Do not use kerosene, diesel fuel, brake cleaner, motor oil or any caustic chemicals. RK recommends that you douse a rag with the mineral based O ring cleaner and wipe the dirt off the chain.

After cleaning the chain and before lubrication, go for a short ride around the block to remove most of the chain cleaner from the chain. RK recommends that you then follow up with a quality chain lubricant and apply to the chain while the chain is till warm.

Missing the Masterlink From A New Chain?

Some RK Chains models will have the master link stored in a separate divided compartment on either end of the chain box. This section may not be visible by simply looking inside the box. Please open both tabs on either side of the box to find the masterlink in this section. If you still cannot find the masterlink – check inside the chain bag.

RK Chain Limited Warranty

RK Chain has an exclusive warranty on all sealed chains NOT used for racing purposes. For street sealed chains not used in racing, there will be a pro-rated 20,000 mile warranty. For off road sealed chain not used for racing there is a 1 year pro-rated warranty. There are some stipulations and conditions to the warranty. For complete information see the warranty section of this website.

- Racing will VOID warranty

- Chain must be appropriate for the motorcycle.

- Chain must have been installed correctly and with drive system properly aligned.

- Chain must have been maintained. NO rust, corrosion, or other signs of neglect.

- Warranty does NOT cover contingent damages.

See warranty card for complete details.

Will I Need Special Tools for Chain Installation?

We recommend that every RK Chain be installed using a chain tool. Some tools, like the RK Chain tool UCT2100(50), combine all the parts needed to break the chain, cut it to length and clip or rivet the connecting link.

Using tools that weren’t designed for chain installation and/or removal may damage your chain and/or cause a dangerous situation and may void your chain warranty.

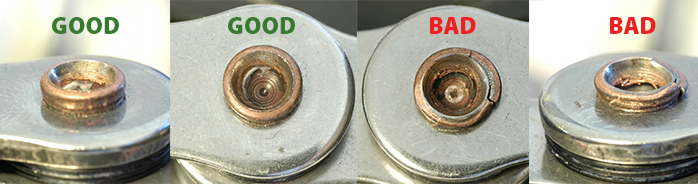

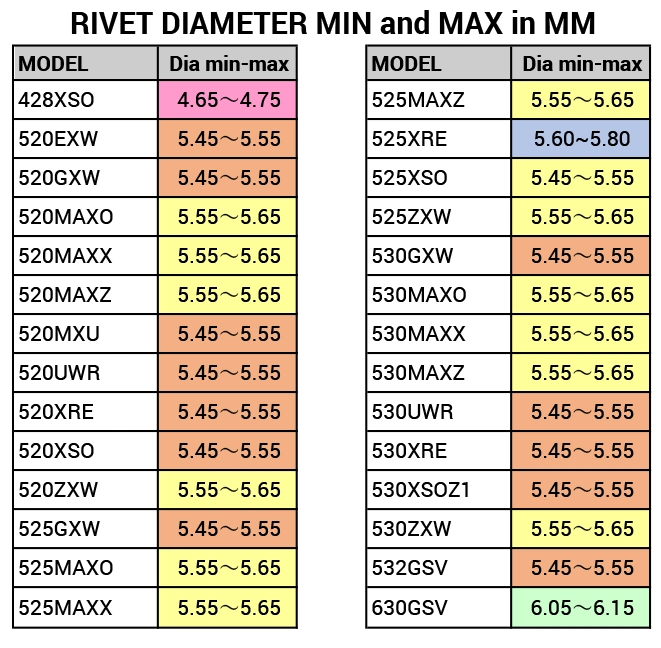

How Much Should I Flare the Rivet Pin When Installing a Rivet Connecting Link?

For RK Chains, reference the chart below for the minimum and maximum rivet diameter in mm. The rivet pin should be flared just enough to keep the sideplate on, but not flared too much to bind the link.

RK’s new UCT2100(50) tool features a newly redesigned Flare Pin Tool that will prevent over-flaring of the rivet pin. *This only applies to the NEW UCT2100(50) tool not previous generations of UCT2100.

Do I Need to Remove the White Grease that Came On My New Chain?

No – You do NOT need to pre-clean a brand new chain. If you feel the quantity of grease is excessive, you can wipe some away. But overall it is not necessary to clean the white lithium grease off of a new chain.

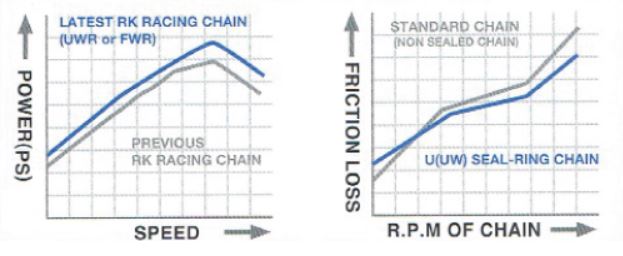

Will I Lose Horsepower by Running A Sealed Chain?

The answer is yes and no. It is true that initially non-sealed chains do produce less friction when compared to sealed chains.

However as time/rpm increase, sealed-ring chains significantly outperform non-sealed chains.

During normal use chains heat up and expand; this expansion can create friction resulting in horsepower loss. Due to the increased internal lubrication of sealed-ring chains, friction is reduced, allowing the chain to more freely transfer horsepower to the ground.

Why Does RK Have So Many Sealed Chains?

RK currently has five types of sealed-ring chains and each has its own features and benefits. After several years of development, RK produced the XW seals which drastically improved the chain life and performance. As racing expanded into several different genres, RK added the ultra thin U-Ring and UW-Ring.

Each seal is specifically designed for a particular use to provide the ultimate in rotating efficiency while providing longer wearlife.

Why Should I Choose an RK Sealed Chain?

1. A sealed chain will last longer. That saves you money in the long-run.

2. Absorbs torque and improves acceleration

RK’s sealed ring chains offer less torsional friction and increased high-stress, high-speed performance. From the beginning of a race to the end; RK’s sealed ring chains deliver more consistent horsepower to the ground than non-sealed chains.

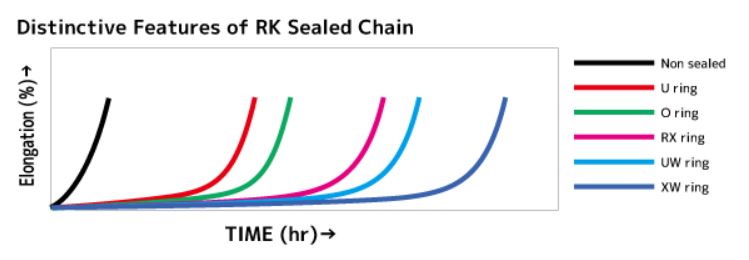

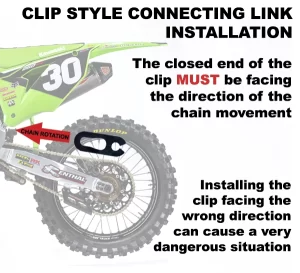

The nitrile butadiene seals ensure that lubrication stays inside the chain while keeping dust and dirt out. Most RK Chain seals have lubrication pools that protect against high speed abrasion, heat buildup, torsional flex and loss of lubricant under extreme conditions, resulting in longer life for the chain and sprockets. The below chart shows that sealed chains can wear longer before the elongation percentage increases.

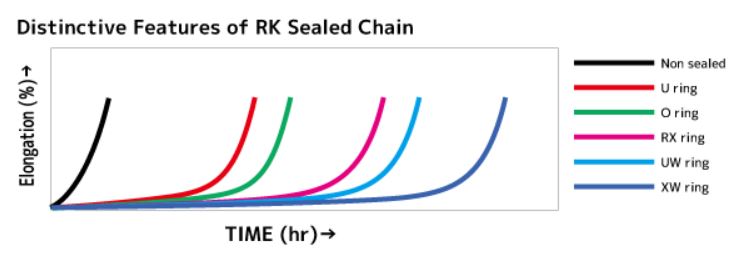

What Is The Difference Between Stamping and Laser Chain Marking?

In the DRIVE CHAIN market, quality requirements are increasing every day with an emphasis on chain weight and strength. Usually the chain maker’s name and chain model are punched on the outer-plates of the chain. These punched marks although mild and shallow, reduce the thickness of the plates and therefore reduce the fatigue resistance strength of the chain. RK Chain modified our method of marking chain from punching to Laser several years ago. The following photos show each marking method.

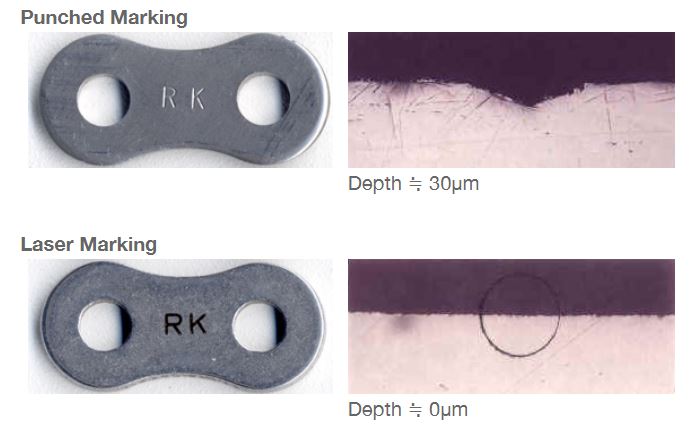

What Direction Should I Install the Clip Link?

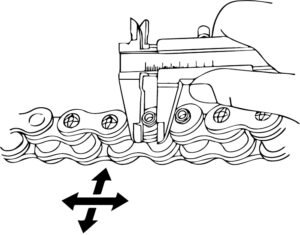

How Do I Count the Number of Links in my Chain?

An easy way of measuring your chain’s length is to count only the outer sideplate pins, as shown in the example. In the example, counting just the pins on the chain gives a total of 28 pins. However, once the master link is added, the chain becomes 30 pins, which means 30 links long. If you purchase 120 link chain, the chain will have 118 pins. Once you add the master link, the total will be 120.

Accurately counting your chain links is crucial, as you cannot add extra links if the chain is too short.

EXCEL RIM FAQ

How Should I Clean My Anodized Rims?

Rims that have been anodized require special care. DO NOT USE SIMPLE GREEN, DEEP PURPLE, OR ANY OTHER CHEMICAL ON ANODIZED RIMS! Cleaning agents can strip the anodizing color away from the rim surface. Cleaning agents should NEVER be allowed to pool on any anodized surface as you may damage the anodizing surface.

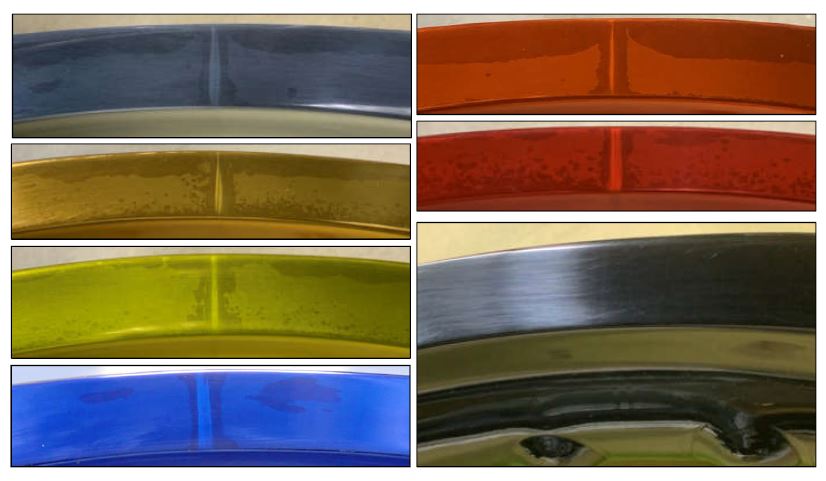

Wash rims with a PH balanced soap (shampoo) using a gentle rag and rinse with water thoroughly. If the cleaning agent is OK for your skin or hair then it will be OK for your rims. It is NOT recommended to use a pressure washer to clean rims. Below is an example of rims that came in contact with a cleaning agent that stripped the blue anodizing upon contact.

My Rims Have Small Cracks Near the Nipples. What Caused This?

Cracks around the nipple holes indicate over-tightening of the spoke and nipples. Nipples should never be over tightened. Whenever you lace or true rims Excel always recommends using a spoke torque wrench. You can maximize your wheel strength by torquing the spokes/nipples to the appropriate specifications suggested by the manufacturer. Excel produces an adjustable torque wrench designed to tighten your nipples to the appropriate specs. See the Excel section of our website for details.

Do Excel Rims Have A Warranty?

Excel Rims do not have a warranty simply because there are too many variables outside of Excel’s control. Variables include rims that are used for racing, wheel lacing, wheel maintenance, proper spoke tensions, environment conditions, and riding styles etc.

When there are issues, we do investigate case by case. But officially Excel Rims do not have any type of warranty.

I Have The Excel Pro Series Gen 1 Hub and Need New Spacers and/or Carriers. What Are My Options?

Excel stopped producing the Excel Pro Series Gen1 hub almost 20 years ago. The redesigned Gen2 Hubs featured stronger technology for the increasing Horsepower of current motorcycles. While replacement product was produced for the Gen 1 hubs for several years after the discontinuation, we have since ceased making any Gen1 product. If you still have a Gen1 hubs and need new spacers, contact us. We will check our inventory to see if we still have the part number. If we do not have the part number we can supply you with the spacer drawings so that you can have a machine shop create the spacers for you.

If you need replacement carriers and we no longer have stock of the part number, then unfortunately you will have to upgrade your wheelset hub and components to the newest generation G2 hubs/carriers. Please note that Gen1 carriers/spacers and Gen2 carriers/spacers re NOT interchangeable. We do offer discounts for these upgrades as long as you send us your current Gen1 hubs/carriers. Call us for details.

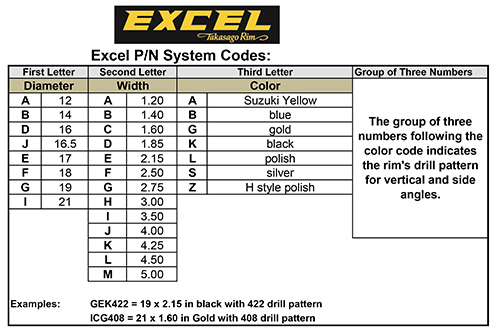

Can I Tell The Size of the Rim by the Part Number Alone?

My Excel Rims Have Splotchy Anodizing!

EXCEL rims made of 7000 series alloy will have the nonuniform color (Segregation) as the pictures above.

This is caused by the structure and composition of 7000 series alloy and becomes visible after anodizing. Technically it is impossible to control (Shape, position, size

and number of the segregation are not controllable and cannot be eliminated).

The segregation of black color is inconspicuous as the dark shade cuts the light reflection through anodizing layer from base aluminum surface.

It varies considerably in appearance, however it is all within our quality standards.

MISC FAQ

My Package Arrived in an Amazon Box. Do you Sell Through Amazon?

Here at RK Excel America Inc, we are environmentally conscious. In order to minimize the impact on our environment, we recycle boxes that are shipped to our facility. Therefore you may receive your package in a recycled box that may or may not have Amazon labeling tape. However RK Excel America does NOT sell any product directly to Amazon.

Do You Sell Direct?

RK Excel America does not sell direct to dealers or the retail public. We prefer that customers find the product they need with their local dealerships. Dealerships looking for product should use their preferred parts distributor. There may be some exceptions for products that are not stocked by distributors, items on closeout or blemished list but these are handled on a case by case basis.

You can visit the blemished/closeout section of our website here.

Do You Have a MAP Policy?

Yes – Both RK Chain and Excel Rims have a MAP Policy that has been in effect since 2015. MAP on all Excel Rims, Spokes and Tool is 10%. RK Chain MAP policy is 10% on most products, with the exception of MAX Chains. MAX chains have 0% MAP.